A pharmaceutical enterprise located in a district of Fuzhou City, known as the “Golden Point” of the global marine golden waterway and situated within the economically vibrant region of southeastern Fujian Province, operates across an area of 180,000 square meters. The company integrates production, research and development, and sales into its operations. After more than a decade of growth, it has achieved industry-leading status in both technological capabilities and production capacity, emerging as a comprehensive, export-oriented pharmaceutical enterprise specializing in biotechnology, antibiotic raw materials, animal drug raw materials, and hypoglycemic raw materials.

The company’s technology center houses specialized laboratories dedicated to microbial breeding and fermentation processes, separation and purification research, and semi-synthetic drug development. During the research and production phases, bioreactors are employed to enhance yield and product quality, reduce manual intervention and associated errors, and minimize environmental impact.

Although the term “bioreactor” may seem unfamiliar to some, its underlying principle is relatively straightforward. For example, the human stomach functions as a complex biological reactor responsible for processing food through enzymatic digestion, converting it into absorbable nutrients. In the field of bioengineering, bioreactors are designed to simulate such biological functions outside the body for the purpose of producing or detecting various chemicals. In essence, bioreactors are systems that utilize the biochemical functions of enzymes or microorganisms to carry out controlled biochemical reactions outside living organisms. These systems serve as biological function simulators, including fermentation tanks, immobilized enzyme reactors, and immobilized cell reactors.

Each stage of the bioreactor process—primary seed culture, secondary seed culture, and tertiary fermentation—is equipped with ProBio pH and DO automatic analyzers. These instruments ensure stable microbial growth while enabling comprehensive monitoring and control of the milbemycin production process. This contributes to consistent and reliable metabolic growth outcomes, resource conservation, cost reduction, and ultimately supports intelligent manufacturing and sustainable development.

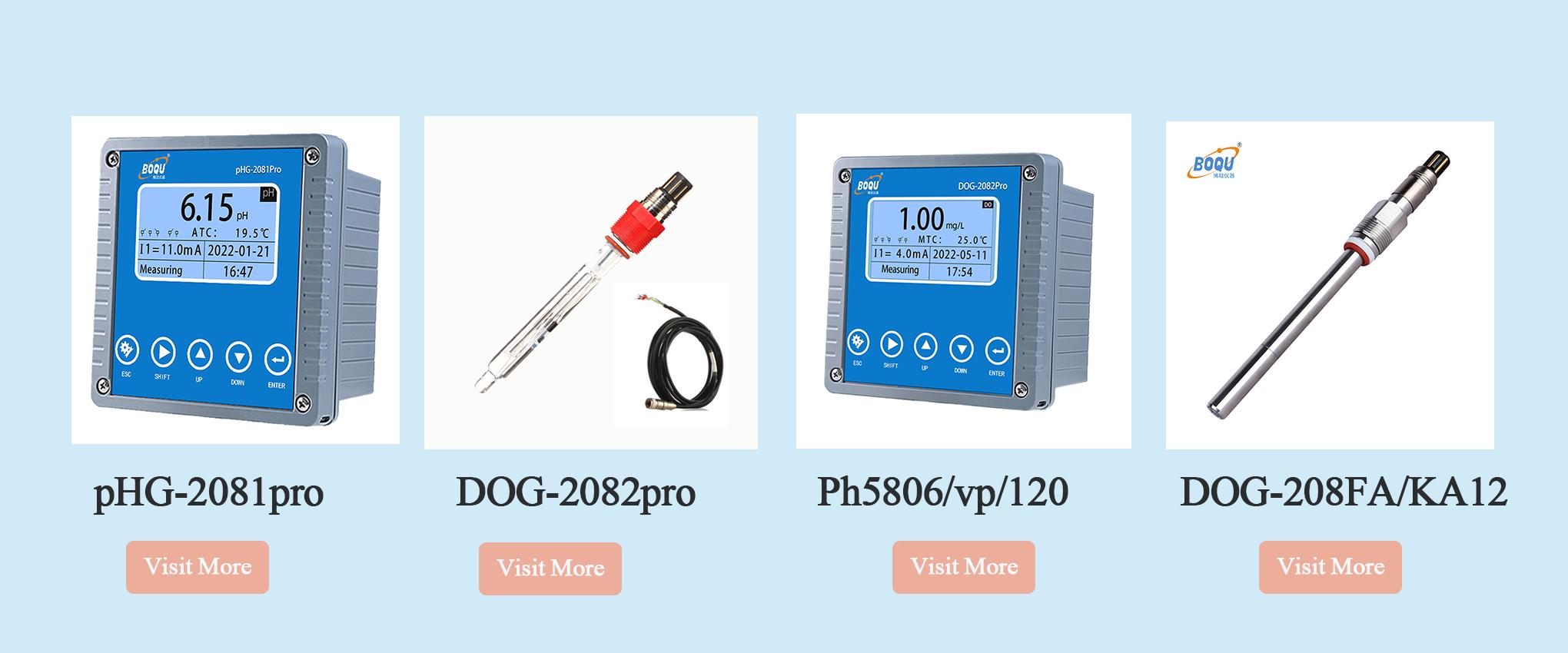

Used Products:

pHG-2081pro Online pH Analyzer

DOG-2082pro Online Dissolved Oxygen Analyzer

Ph5806/vp/120 Industrial pH Sensor

DOG-208FA/KA12 Industrial Dissolved Oxygen Sensor