A high-temperature fermentation manufacturing company in India monitors the liquid in the fermentation to promote the growth of microorganisms in the most suitable pH range and ultimately synthesize target metabolites. Therefore, the pH value needs to be strictly controlled during the fermentation process. Dissolved oxygen is an important parameter in microbial fermentation control, which directly affects the stability and production cost of fermentation production.On the one hand, controlling the dissolved oxygen in fermentation liquid can improve the growth and metabolism environment of microorganisms and effectively promote the accumulation of beneficial metabolites during the fermentation process. On the other hand, it can also save energy and reduce consumption, which is of great significance to the production of enterprises.Especially for high-density fermentation, improving the dissolved oxygen condition of fermentation liquid is the key factor to promote product synthesis.Therefore, fast and accurate online monitoring of numerical changes and timely adjustment of numerical values are a key factors for the final success of fermentation.

Using products:

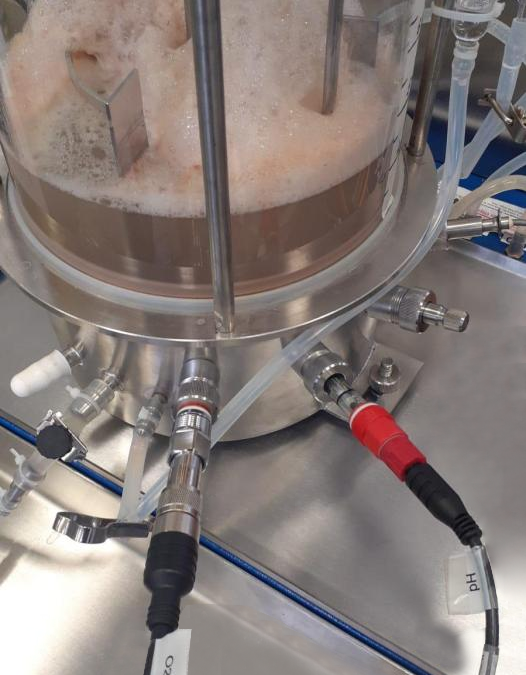

pHG-2081Pro Industrial pH Analyzer

pH-5806 High temperature pH Sensor

DOG-2082Pro Industrial dissolved oxygen analyzer

DOG-208FA High temperature dissolved oxygen sensor

VP6 VP Cable

The high-temperature fermentation company in India installed BOQU's pH and dissolved oxygen meters to intelligently monitor and adjust pH and dissolved oxygen values, so that the fermentation process can be controlled.The quality of fermentation products is ensured while the yield is increased.