This pharmaceutical company is a large-scale enterprise that integrates research, development, production, and sales of medicines. Its core product line consists of large-volume injections, complemented by a comprehensive range of supporting products including antipyretics and analgesics, cardiovascular medications, and antibiotics. Since 2000, the company has entered a phase of rapid growth and gradually established itself as a leading pharmaceutical enterprise in China. It holds the prestigious title of a national high-tech enterprise and has been recognized as a “National Trusted Brand for Medicines” by consumers.

The company operates seven pharmaceutical manufacturing facilities, one pharmaceutical packaging materials plant, six pharmaceutical distribution companies, and one major pharmacy chain. It possesses 45 GMP-certified production lines and offers products across four major therapeutic categories: biopharmaceuticals, chemical pharmaceuticals, traditional Chinese patent medicines, and herbal decoction pieces. These products are available in more than 10 dosage forms and encompass over 300 distinct varieties.

Applied Products:

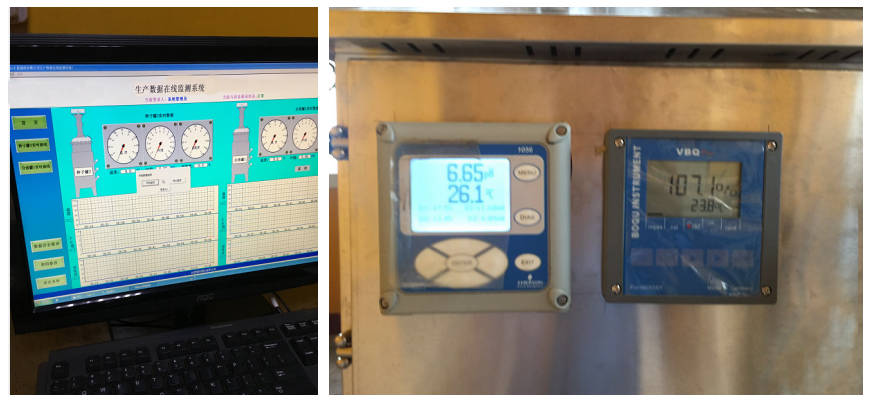

pHG-2081Pro High-Temperature pH Analyzer

pH-5806 High-Temperature pH Sensor

DOG-2082Pro High-Temperature Dissolved Oxygen Analyzer

DOG-208FA High-Temperature Dissolved Oxygen Sensor

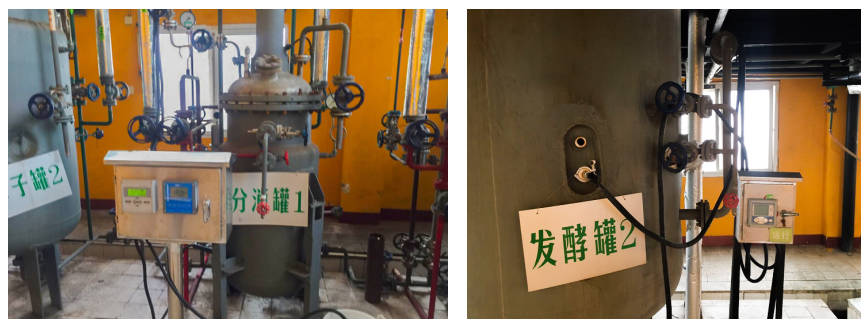

Within its antibiotic production line, the company utilizes one 200L pilot-scale fermentation tank and one 50L seed tank. These systems incorporate pH and dissolved oxygen electrodes independently developed and manufactured by Shanghai BOQU Instrument Co., Ltd.

pH plays a critical role in microbial growth and product synthesis. It reflects the cumulative outcome of various biochemical reactions occurring during the fermentation process and serves as a key parameter for monitoring and controlling fermentation conditions. Effective measurement and regulation of pH can optimize microbial activity and metabolic efficiency, thereby enhancing overall production performance.

Dissolved oxygen is equally essential, particularly in aerobic fermentation processes. Adequate levels of dissolved oxygen are vital for sustaining cell growth and metabolic functions. Insufficient oxygen supply may lead to incomplete or failed fermentation. By continuously monitoring and adjusting dissolved oxygen concentrations, the fermentation process can be effectively optimized, promoting both microbial proliferation and product formation.

In summary, precise measurement and control of pH and dissolved oxygen levels contribute significantly to improving the efficiency and quality of biological fermentation processes.