A certain paper industry limited liability company located in Fujian Province is one of the largest paper production enterprises in the province and a key provincial enterprise integrating large-scale papermaking with combined heat and power generation. The total construction scale of the project includes four sets of “630 t/h high-temperature and high-pressure multi-fuel circulating fluidized bed boilers + 80 MW back-pressure steam turbines + 80 MW generators,” with one boiler serving as a backup unit. The project is implemented in two phases: the first phase consists of three sets of the aforementioned equipment configuration, while the second phase adds one additional set.

Water quality analysis plays an essential role in boiler inspection, as water quality directly impacts boiler operation. Poor water quality may lead to operational inefficiencies, equipment damage, and potential safety hazards for personnel. The implementation of online water quality monitoring instruments significantly reduces the risk of boiler-related safety incidents, thereby ensuring the safe and stable operation of the boiler system.

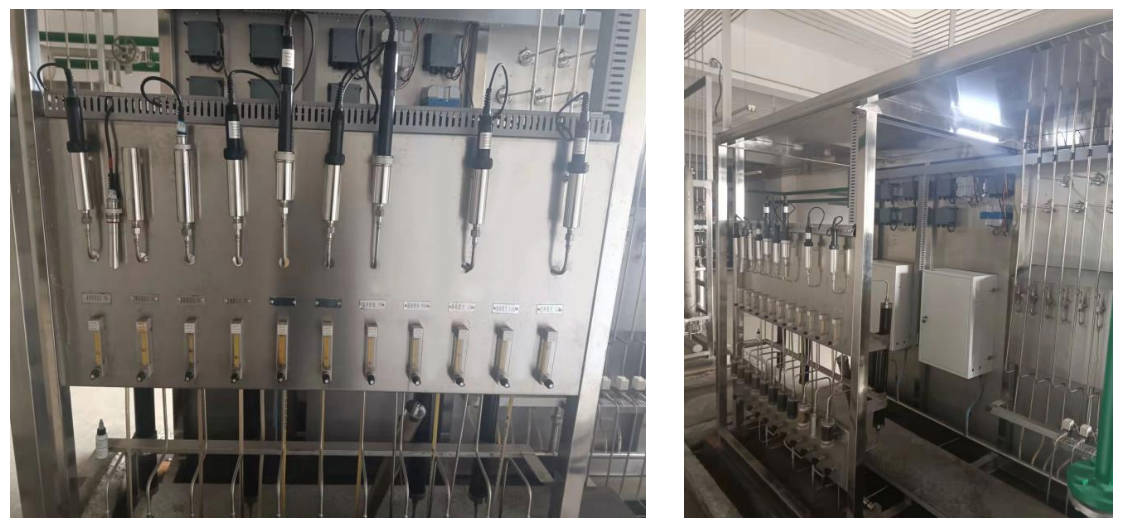

The company has adopted water quality analysis instruments and matching sensors produced by BOQU. By monitoring parameters such as pH, conductivity, dissolved oxygen, silicate, phosphate, and sodium ions, it ensures the safe and stable operation of the boiler, extends the service life of the equipment, and guarantees the quality of steam.

Used Products:

pHG-2081Pro Online pH Analyzer

DDG-2080Pro Online Conductivity Analyzer

DOG-2082Pro Online Dissolved Oxygen Analyzer

GSGG-5089Pro Online Silicate Analyzer

LSGG-5090Pro Online Phosphate Analyzer

DWG-5088Pro Online Sodium Ion Analyzer

pH value: The pH of boiler water needs to be maintained within a certain range (typically 9-11). If it is too low (acidic), it will corrode the metal components of the boiler (such as steel pipes and steam drums). If it is too high (strongly alkaline), it may cause the protective film on the metal surface to fall off, leading to alkaline corrosion. An appropriate pH can also inhibit the corrosive effect of free carbon dioxide in the water and reduce the risk of pipe scaling.

Conductivity: Conductivity reflects the total content of dissolved ions in water. The higher the value, the more impurities (such as salts) are present in the water. Excessively high conductivity can lead to boiler scaling, accelerated corrosion, and may also affect steam quality (such as carrying salts), reduce thermal efficiency, and even cause safety incidents such as pipe bursts.

Dissolved oxygen: Dissolved oxygen in water is the main cause of oxygen corrosion of boiler metals, especially in economizers and water-cooled walls. It can lead to pitting and thinning of the metal surface, and in severe cases, equipment leakage. It is necessary to control the dissolved oxygen at an extremely low level (usually ≤ 0.05 mg/L) through deaeration treatment (such as thermal deaeration and chemical deaeration).

Silicate: Silicate is prone to volatilize with steam under high temperature and pressure, depositing on turbine blades to form silicate scale, which reduces turbine efficiency and even affects its safe operation. Monitoring silicate can control the silicate content in boiler water, ensure steam quality, and prevent turbine scaling.

Phosphate root: Adding phosphate salts (such as trisodium phosphate) to boiler water can react with calcium and magnesium ions to form soft phosphate precipitates, preventing the formation of hard scale (i.e., “phosphate scale prevention treatment”). Monitoring the concentration of phosphate root ensures it remains within a reasonable range (typically 5-15 mg/L). Excessively high levels can lead to phosphate root being carried by steam, while levels that are too low will fail to effectively prevent scale formation.

Sodium ions: Sodium ions are common salt-separated ions in water, and their content can indirectly reflect the concentration degree of boiler water and the situation of salt carried by steam. If the concentration of sodium ions is too high, it indicates that the boiler water is seriously concentrated, which is prone to cause scaling and corrosion; excessive sodium ions in steam will also lead to salt accumulation in the steam turbine, affecting the performance of the equipment.